Neutralization tank maintenance…….

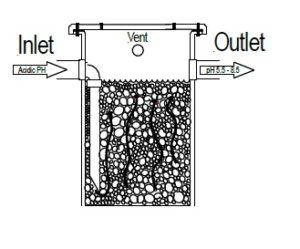

Proper maintenance of neutralization tanks is essential for proper neutralization of wastes in the systems. Over time, limestone will loose there ability to effectively neutralize effluents. Tanks must be cleaned out periodically of all sludge, debris and other material and must be checked for proper amount of limestone. A regular maintenance schedule of one to three months should be observed, but more or less frequent inspection may be necessary in any particular case.

A great way to keep track of inspections is to use a log attached near the tank that records and schedules inspections. This ensures that the tank is being inspected and is also a visual reminder in case there is a change in personnel responsible for the tank. It is also a great way to show state and federal regulators (like EPA or OSHA) that the tank is being properly maintained for your effluent. If you are going to clean out the tank, check your local regulations for proper limestone and sludge disposal. There are also commercial contractors who will come clean the tank for you.

Scientific Plastics manufactures a full line of under counter and large system tanks. You can find us on the web or call us at: 913.432.0322